Rotation stages, often called index tables or rotary tables, are mechanisms used to precisely rotate a sample or specimen with high angular accuracy. Motorized rotary stages make use of a motion controller and stepper motor or - when higher performance is required - closed-loop servo motor, position feedback and computer control. Better performance, speed control and higher acceleration is achieved when using a direct-drive rotary table. For test of optics, often rotary air bearings are used, because of their extremely low excentricity and wobble.

PI provides a wide variety of precision rotation stages for high-accuracy and standard precision positioning applications.

Different stage drive concepts, from ironless piezo-motors, air-bearings / torque motors to compact worm-gear rotary positioners with encoded and open-loop stepper-motors to the ultra-low profile, self-locking piezo-motor rotation stages are available in standard and custom designs. Air bearing stages provide extremely accurate motion with minimum wobble and excentricity and are recommended for applcations such as X-ray crystallography.

Piezo-motor-driven stages are self locking at rest, a great advantage when it comes to long term stability and when applications require power to be shut down. The low inertia of the piezo-rotation stages also enables very fast step and settle with minimum overshoot.

In addition to classical worm gear rotation stages for ambient and vacuum environments, goniometer cradles are available, tip/tilt positioners , piezo mirror rotators with fixed center of rotation and even multiaxis parallel positioners such as hexapods with fully programmable center of rotation for three rotary axes.

Miniature and sub-miniature rotary positioners are now available in a variety of sizes, with profiles as low as 7 mm and rotation speeds as high as 1000 deg/sec.

Most positioning systems are also available for vacuum and high vacuum environments.

PDF Brochure: Motorized Ultra High Accuracy Rotation Stage Brochure

The Video shows a High Accuracy, High Velociy Rotary Table with Air Bearings and Absolute Encoder

|

| ||

V-610 Compact, High Speed Direct-Drive Rotary Table with Ironless 3-Phase Motor

| ||

|

This compact closed-loop direct drive rotary table uses a 3-phase motor for maintenance free, frictionless power transmission. It comes in two variations, standard and with holding brake.

| |

|

| ||

V-622, V-623 High Performance Direct-Drive Rotary Table with Ironless 3-Phase Motor, for Industrial Applications

| ||

|

V-62x series direct-drive ball-bearing rotation stages are designed for extreme precision, based on PI's experience with ultra-precise air bearing rotary tables. They provide high stiffness, a long lifetime, and ease of use, and can operate in any orientation. The V-62x stages offer superior performance regarding accuracy, resolution, reppeatability as well as geometric performance such as flatness, and wobble. The ultra-precise deep groove ball bearings are preloaded and lubricated prior to delivery,meaning they are maintenance-free for the whole lifetime of the rotation stage.

| |

Ultra-Low Profile Direct-Drive Rotation Table with Fast Ironless Piezo-Motor

| ||

The M-660 / U-651 hich accuracy rotation table is the lowest profile rotary stage with high-speed direct-drive piezoceramic motors on the market. This ironless drive can move at very slow speeds and accelerate quickly to velocities of 720 degrees/sec. Its directly coupled precision optical encoder resolves positions down to 4 Árad (0.00023░), providing phase-lag-free, backlash-free feedback to the servo controller. The self-clamping ceramic drive provides very high stability, with no energy consumption at rest and no heat generation

|

| |

|

| ||

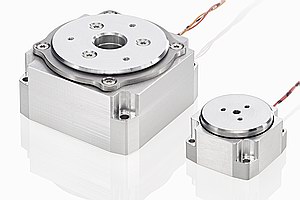

U-628 High-Speed Miniature Direct Drive Rotation Table with Piezo Motor: 720 Deg/Sec

| ||

|

|

This miniaturized closed-loop rotary positioner is driven by an ultrasonic direct-drive motor and provides high rotational velocity up to 3 revolutions / second. An optical encoder is integrated for direct position measurement and feedback with 35 Árad resolution.

| |

U-624 / U-622 High Resolution Sub-Miniature Rotation Stage with Fast Ultrasonic Motor

| ||

|

This sub-miniature rotation stage is available in vacuum and standard versions. Two sizes are available: ě30x12mm and ě20x10mm.

A fast ultrasonic ceramic ring-shaped resonator motor provides high speed to 120 RPM. An optical direct metrology encoder is integrated for position feedback.

| |

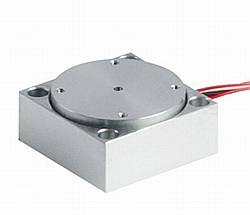

Ultra-Low Profile Mini Rotation Stages with Stick-Slip Piezo Motors

| ||

|

Q-motion series miniature rotation stages are driven by inertia-type piezo motors. These miniaturized positoining tables are direct-driven, backlash free and provide micro-radian resolution. The self-locking design requires no holding current and provides excellent long-term stability. Three different diameters are available: 14 mm, 22 mm and 32 mm.

| |

Air-Bearing Ultra-High Precision Direct Drive Rotary Tables, Motorized Rotation Stages and Spherical Air Bearings

| ||

620-Series Family of Rotary Air Bearing Stages - mount in any orientation

Low profile air bearing rotary table, directly driven with 3-phase motor, for horizontal mount

Custom 300mm Air Bearing Stage Read Article Large Air Bearing Rotary Table for Synchrotron Crystallography |

PI's air-bearing rotation stages provide the highest accuracy and smoothest motion of any commercially available rotation stage. With standard and custom designs these stages are designed for reference class applications.

| |

Vacuum Compatible Precision Rotation Stage, High Load / Worm Gear

| ||

|

PRS-200 rotation stages can handle high loads to 50 kg and come with a large aperture for photonics and optics applications.

Stepper and servo motors are availabe, direct metrology encoders are optional and a high-vacuum version is also available.

| |

M-06x Precision High-Resolution Rotation Tables / Worm Gear Driven | ||

|

M-06x series rotation stages are equipped with ultra-precise, ultra-low-friction,

spring-preloaded worm gear drives allowing unlimited rotation in either direction. Three

different turn-table diameters are available: 60 mm, 100mm and 120mm.

Drive Options: Servo Motor, Stepper Motor and Manual

Three motor drives are available: Open-Loop Stepper Drives and two closed-loop servo

drives with different resolution / speed rating.

| |

M-116 Precision Miniature High-Resolution Rotation Table Compact / Worm Gear Driven

| ||

|

M-116 rotation stages are equipped with low-friction, spring-preloaded worm gear

drives allowing unlimited rotation in either direction in an extremely compact package.

| |

Additional Precision Rotation Stages and Goniometer Cradles from PI miCos | ||

| ||

The PI miCos line of goniometers and rotation stages is specialized on miniature stages with different motor drives (belt-drives, worm-gear drives) and also on ultra-high precision stages with torque motors, direct metrology and air bearings.

Most stages are available in high vacuum and UHV specification.

Overview / Specifications of PI miCos precision rotary positioners and goniometers |

||

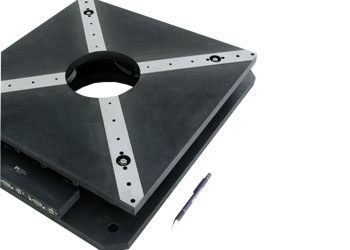

M-880 Rotation + XY Stage: Planar 3-Axis Precision Positioner XY-Rot-Z Parallel Kinematics System with Very High Holding Force | ||

|

This parallel-kinematics 3-axis precision positioning system combines rotation around Z

and linear travel in the X and Y axes in a very low profile package.

The extremely low profile of just 105 mm is made possible because all actuators are

directly connected to the single moving platform, as opposed to stacking a rotation stage

on top of an XY table.

| |

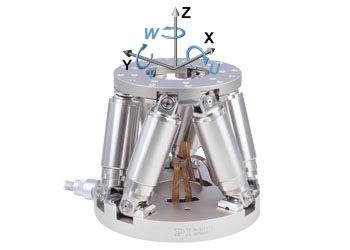

M-811 Vacuum-Hexapod: 3 x Rotation + XYZ = 6 DOF, High Precision and Very Versatile

| ||

|

This Hexapod provides 6 degrees of freedom: rotation around 3 axes and 3 linear motions in one compact, vacuum-compatible package. It can handle loads up to 11 lbs (5kg) and move at velocities to 10 mm/sec. The combination of linear motion and rotation angles of 20░ around the X and Y axis and up to 40░ around the vertical axis allows for complex motion profiles with particularly flexible placement of the load - a great advantage in restricted areas (such as beam lines) and small vacuum chambers.

| |

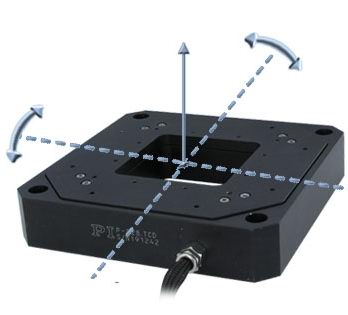

P-528 Precision Piezo Z/Tip/Tilt Stage: 2 x Rotation + Z

| ||

|

P-5x8 series, Z/tip/tilt nanopositioners are open-frame, high-resolution, piezo-driven stages providing Z motion to 240 Ám and rotation around X and Y to 2.4 mrad with resolutions of up to 0.5 nm and 50 nrad. The 66 x 66 mm clear aperture is ideal for transmitted-light applications.

| |

Goniometer Cradels: Precision Rotation with a fixed Pivot Point | ||

|

Goniometric cradles are used to rotate samples and objects to a precise angular position. The units here are equipped with precision servo and stepper motors and high-resolution encoders for angular position feedback.

|

|

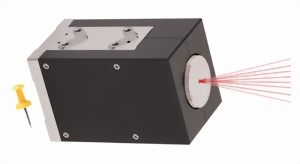

S-335 2-Axis Rotational Piezo Mirror Positioner, Fast Steering Mirror with up to 70 mrad Deflection

| ||

|

The S-335 miniature platforms rotate a mirror up to 35 mrad (70 mrad optical deflextion) around the X and Y axes. These fast mirror scanners are based on solid-state piezo drives and a parallel-kinematics flexure guiding system, with two coplanar, orthogonal axes and a fixed pivot point.

| |

|

| ||

S-340 2-Axis Rotational Piezo Mirror Positioner, Fast Steering Mirror for Optics to 4ö Diameter | ||

|

This piezo platform can rotate a mirror or optic up to 2 mrad (4 mrad optical deflection) around two orthogonal axes. The parallel-kinematic, solid-state piezo drive system guarantees exceptional precision and very fast response in the low millisecond range and below. PDF Brochure | Request Quote | |

S-224 Piezo Mirror Tilter: Rotation with 50 Nano-Radian Resolution

| ||

|

S-224/S-226 miniature tilt platforms provide rotation of 2.2 mrad around the Y-axis. They are extremely fast with resonse in the microsecond range. A ě15x4mm BK7 glass mirror is mounted.

| |

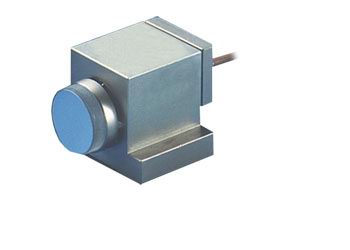

Two ultrasonic piezo motors driving a circular ceramic runner in an M-660 rotation stage |

Ultra-slow motion animation of the PILine« ultrasonic piezo motor. The ceramic tip (pusher) is moving on an pseudo-elliptical trajectory. In reality the tip only moves a few nanometers at frequencies to 100's of kHz. | |